- дом

- Сервосистема

- Solution of SD700 on Vertical Packaging Machine

Industry introduction

Vertical packaging machines are mainly used for packaging liquids, powders, granules, and other food or medicines that are not suitable for horizontal packaging. The packaging process is divided into horizontal pull-type, back pull-type, and continuous type. In terms of the bagging effect, it can be divided into a three-side seal, four-side seal, back seal, pin, and so on. At the same time, when packing different materials, it is also necessary to be equipped with different feeding mechanisms, such as screw scales, combination scales, measuring cups, etc.

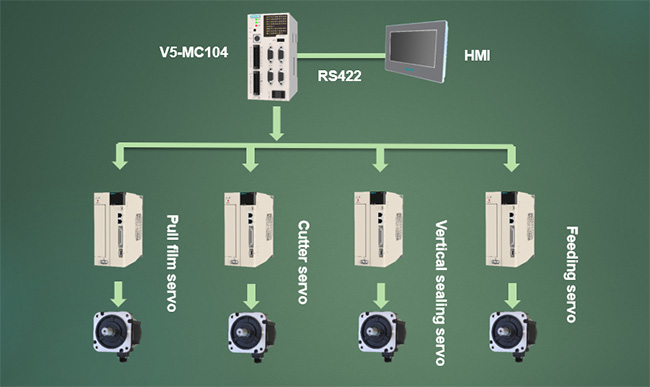

System topology

Program highlights

1. The system adopts VEICHI V5-MC104 motion controller, dual CPU hardware architecture, and the underlying processing speed is faster.

2. Man-machine interface centralized control, stable performance, easy to operate and maintain.

3. Use an electronic cam algorithm to replace the traditional mechanical cam, simplify mechanical design and improve equipment performance.

4. The connection between the V5 controller and servo adopts a high-speed differential signal, which has high stability and is not easy to interfere with. The maximum pulse speed of the differential pulse port is 3MHz, which can achieve extremely high control accuracy.

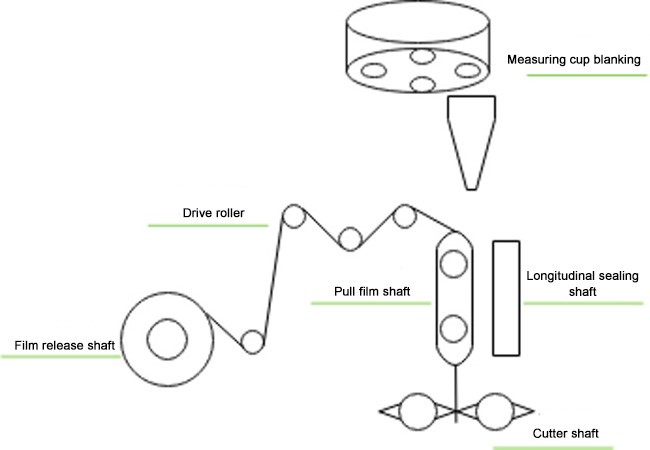

Process principle

The structure of the vertical packaging machine is mainly composed of the following parts:

1. Film feeding mechanism: mainly composed of grinding roller and film feeding shaft. The main purpose is to smooth the packaging film and evenly send it to the lapel former. The film feeding shaft is connected with a servo, and the middle is driven by a belt.

2. Cutter mechanism: Under V5 control, follow the main shaft for flying shear motion control, and follow the main shaft motion along the set cam flying shear curve.

3. Longitudinal sealing mechanism: Under V5 control, use the built-in electronic cam to follow the main shaft for tracking shear motion control. During the synchronization zone, the heat-sealing module is closed and opened to realize the heating and middle-sealing function of the packaging bag.

4. Measuring cup mechanism: This shaft is the same as the horizontal sealing shaft, which makes the material in the measuring cup fall evenly, and realizes the function of cutting a film length and dropping the measuring cup into a groove.

Technical index

The tracking accuracy is ±1mm.

The horizontal pulling speed is 90 packs/min.

The film drawing speed is 24 meters/min.

The continuous speed is 150 packs/min.

Application

Global - English

Global - English Spanish - Español

Spanish - Español French - Français

French - Français Russian - Pусский язык

Russian - Pусский язык Chinese - 中文

Chinese - 中文 Korean - 한국어

Korean - 한국어 Vietnamese - Tiếng Việt

Vietnamese - Tiếng Việt

Оставить сообщение

Оставить сообщение